Workshop on Defects

Once, someone told me there are only two types of brewers: the ones who have already contaminated some beer and those who will let it contaminate one day. It is likely that the contaminations might take place for different reasons, if no measures will be taken care during the elaboration process.

It is through the senses (touch, sight, smell, hearing and taste) and corresponding sensory experiences that a beer’s virtues or defects are measured. Although a sensory analysis capability is required to distinguish the aromas and flavors inherent in a beer, it is also essential to determine the presence of any defects. These indicate problems of sanitization, poor quality of ingredients, failures during fermentation, etc.

Proper analysis of anomalies in a beer allows us to determine and resolve during that very stage where the problem occurred, and to implement appropriate control measures so that they do not occur again.

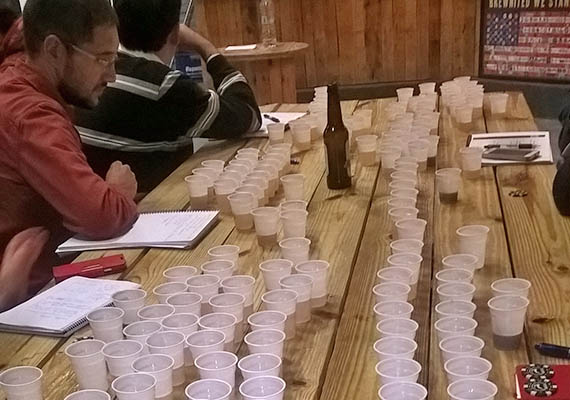

In this workshop we looked at a series of beers prepared with the most common defects found in beers. Some of the off-flavors/ aromas explored:

Acetaldehyde

Astringet

Diacetyl

DMS

Metallic

Estery

Sour/Acidic

Oxidized

Sulfury

Solvent/Fusel

Phenolic (Smoky/Spicy)

Yeasty